- (203) 878-4648

- Toll Free: (800) 539-0193

- info@interfacedevices.com

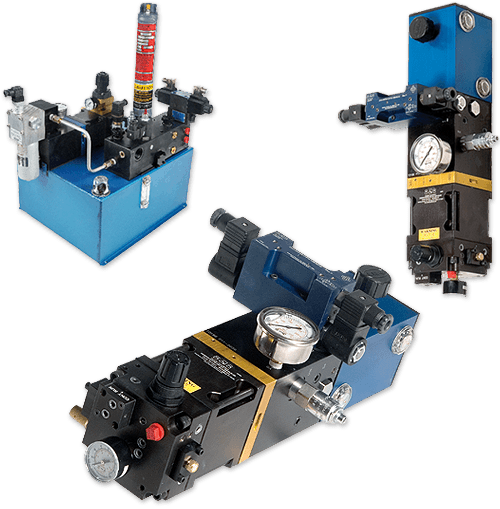

E, H & P Series Air-driven Liquid Pumps for Fluid Power Applications

Customizable configurations, countless integrated pneumatic and hydraulic circuit options and pressures to 10,000 psi (680 bar)

E, H & P Series are compressed air-driven, positive-displacement intensifier pumps. Ideally suited for hydraulic applications with intermittent flow and pressure demands, E, H & P Series pumps utilize factory customized hydraulic and pneumatic circuitry.

Pump system integration eliminates the need for plumbing, line-mounted items and external manifolds and eliminates the increase in leak points that are prevalent in most hydraulic pump systems. This makes for a "plug & play" package that is easy to install and operate with nearly limitless functions.

Air-driven liquid pumps are ideal for applications where a constant pressure is required, especially over longer periods of time. If no leaky valves are used in the application, the intensifier pump will hold pressure for days on end without consuming any energy or generating heat. Since all moving parts are non-ferrous and there is no metal-to-metal contact, the pumps are suitable for use in classified (explosion-proof) or Hazmat environments. They can be an economical alternative for traditional electric Hydraulic Power Units in many applications.

Click here for E, H & P Series air-driven liquid pump accessories.

Features & Benefits

Air-driven Intensifier, Positive-displacement Operation

- Consumes no compressed air or electric power while maintaining pressures up to 10,000 psi (680 bar) for hours on end.

- Does not generate heat during the pump cycle or while maintaining pressure. Eliminates need for oversized oil reservoirs or heat exchangers present in many hydraulic pump systems.

- Nearly 100% efficient, so no energy is wasted in achieving the task at hand.

Integrated Hydraulic and Pneumatic Circuitry

- Reduces installation and operation cost associated with excessive plumbing and maintenance of externally plumbed components.

- Neat and tidy in appearance, reflecting a higher level of quality for the entire system.

- Offers flexibility during the specification process to give engineers and hydraulic specialists more leeway in the design process.

Compact and Lightweight

- Allows for portable operation. Most systems weigh less than 25 lbs (11.5 kg).

- Easy to install. Most systems require an air connection and two hydraulic lines.

- Makes replacement and maintenance less labor intensive.

Aerospace-grade Dynamic Seals

- Provides operational longevity with minimal risk of leakage.

- "Dry" operation; no lubrication required.

- Saves on maintenance and spare parts cost.

Documentation

Brochure (PDF)

Manuals (PDF)

Performance Curves (PDF)

General Arrangements / Dimensions (PDF)

Schematics (PDF)

Presentations (PPS)

» Read more about E, H & P Series pumps.

Because of their versatility, E, H & P intensifier pumps are well suited for a huge variety of applications. Air-driven liquid pumps are used in many power workholding applications. The ability to customize IDI air-driven pumps allows for the design and integration of multiple circuits and functions into one workholding application. Most power workholding is done at high pressures – in excess of 3500 psi (238 bar). To reduce wear and tear on the pumps, IDI provides poppet-style zero-leak 3- and 4-way directional control valves. These ensure that the pump stalls at pressure and does not cycle unnecessarily, which can stress all of a system's components.

E, H & P Intensifier Pumps are additionally used in a variety of industrial machines for die holding and die change, counter weights, tensioning and controlling the force and positioning of rolls on milling machines.

Air-driven pumps are also used with tools such as rivet setting tools, rescue tools including the Hurst Jaws of Life® and hydraulic torque tools.

The ability to create a custom solution for a unique application in the same amount of time that most companies need to deliver a standard product makes IDI's custom air-driven liquid pumps unique in the field.