- (203) 878-4648

- Toll Free: (800) 539-0193

- info@interfacedevices.com

The IDI Difference

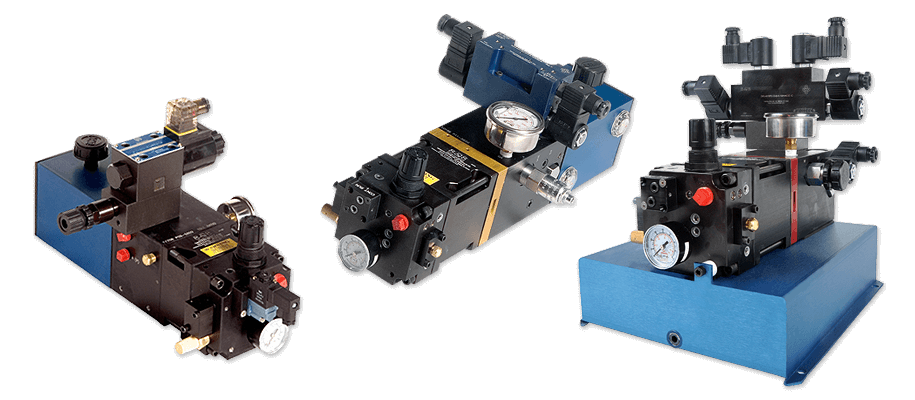

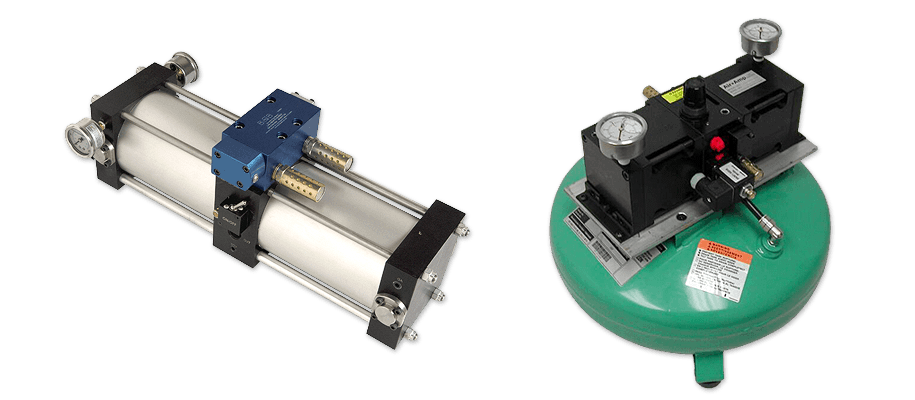

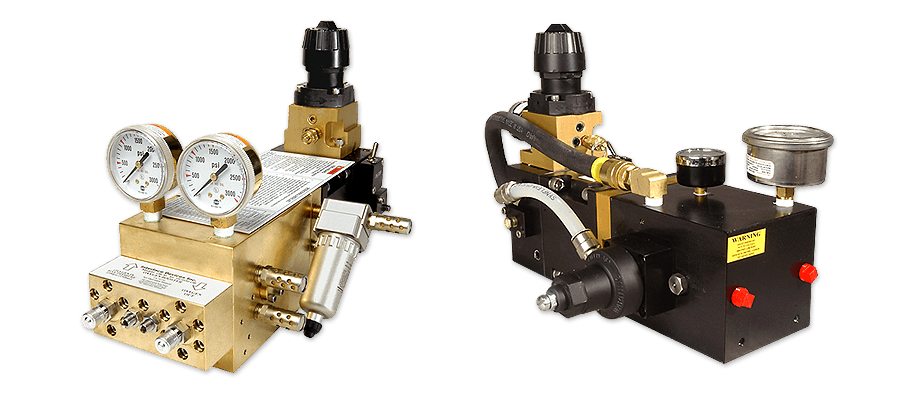

Interface Devices is one of the industry's most trusted manufacturers of air-driven liquid pumps, hydraulic valves, air and gas boosters, air amplifiers and custom-engineered fluid power products. IDI products are durable, compact, customizable and efficient – and more cost effective than you may think!

Discuss your requests, application or support...

- +1 203-878-4648

- Toll Free: 800-539-0193

- Quick Form

- » Distributors Only

Why Work with IDI?

At IDI, we pride ourselves on manufacturing outstanding products and providing superior service, and a live voice will always greet you when you call during business hours. IDI's knowledgeable, highly experienced staff will provide you with honest advice and standout support every step of the way, from design consultation through post-install troubleshooting and prompt repairs. Quick shipment of in-stock parts is typically available. Read more about what sets us apart from the competition. »

SpaceX

IDI has provided multiple valves to assist with actuating the enormous hydraulic cylinders that lift the SpaceX Falcon 9 rocket into launch position. SpaceX intends to launch the largest rocket ever built next year, powering its "Falcon Heavy" with 27 engines (compared to the 9 on the current Falcon 9). These rockets are a reusable means of providing supplies to the International Space Station, with aspirations for more space exploration uses in the future.

Hurst Jaws of Life® Tools

As a longstanding supplier of highly specialized power units and valves for Hurst's product lines, IDI has custom built units that allow first responders to use available air bottles (commonly known as "Scot Packs") to power the hydraulics on the Jaws of Life® tools. This eliminates the need for gas-driven engines that have limitations in portability and range of operation.

Oil Platform "PROD" System

IDI has a lengthy standing relationship with Lanmar Logistics in Canada, a company that developed a system allowing personnel on offshore oil rigs to be safely evacuated to the ocean during emergencies. The "PROD" System is essentially a large arm powered and stabilized by hydraulics that keeps transportation and emergency boats from being destabilized during deployment, particularly under inclement weather conditions.

Jet Packs

IDI nitrogen boosters are used by Jet Pack International as an affordable and portable way to refill their packs' engines with compressed nitrogen – a component that is vital to their operation. These jet packs hold numerous world records for flight duration and altitude, including a little excursion over the Grand Canyon.

Aviation Ground Support Equipment (GSE)

IDI manufactures a line of purpose-built equipment for servicing aircraft, including gas boosters used for on-board systems and portable hydraulic "mules" used for testing functions such as landing gear. IDI ground support systems have been used all over the world, including Iraq and Afghanistan. Major aircraft companies such as FedEx, United and McDonnell Douglas have used IDI-manufactured GSE.

Watch now: IDI was featured as an industry leader on the World's Greatest!... cable television show.

[ Run time: 3 min. 32 sec. ]

Headlines

- Two Industry Leaders Work Together to Provide the Ultimate Fluid Power Solutions

- IDI Air-driven Liquid Pumps Help Unique Automation Deliver Under Challenging Conditions

- Partnership Between Interface Devices and Engineered Inserts & Systems Benefits More than the Bottom Line

- World-class Machine Integrator Uses IDI Pumps as Part of its Customization Process

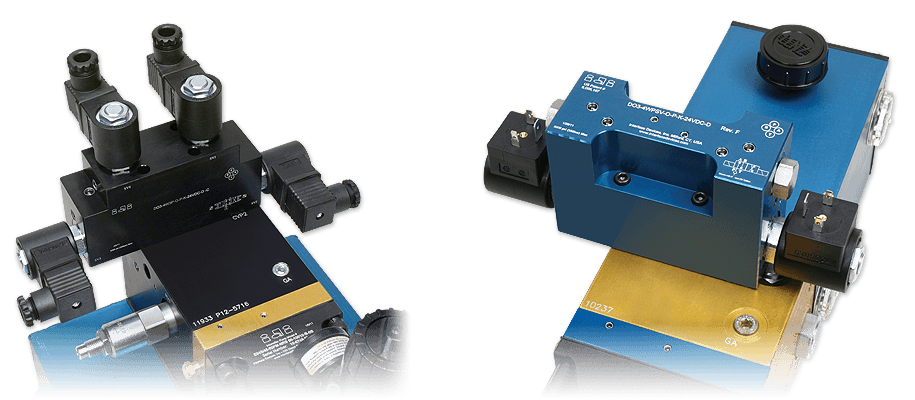

- Update: D03 Solenoid Poppet Valves Chosen for Private Space Launch Application